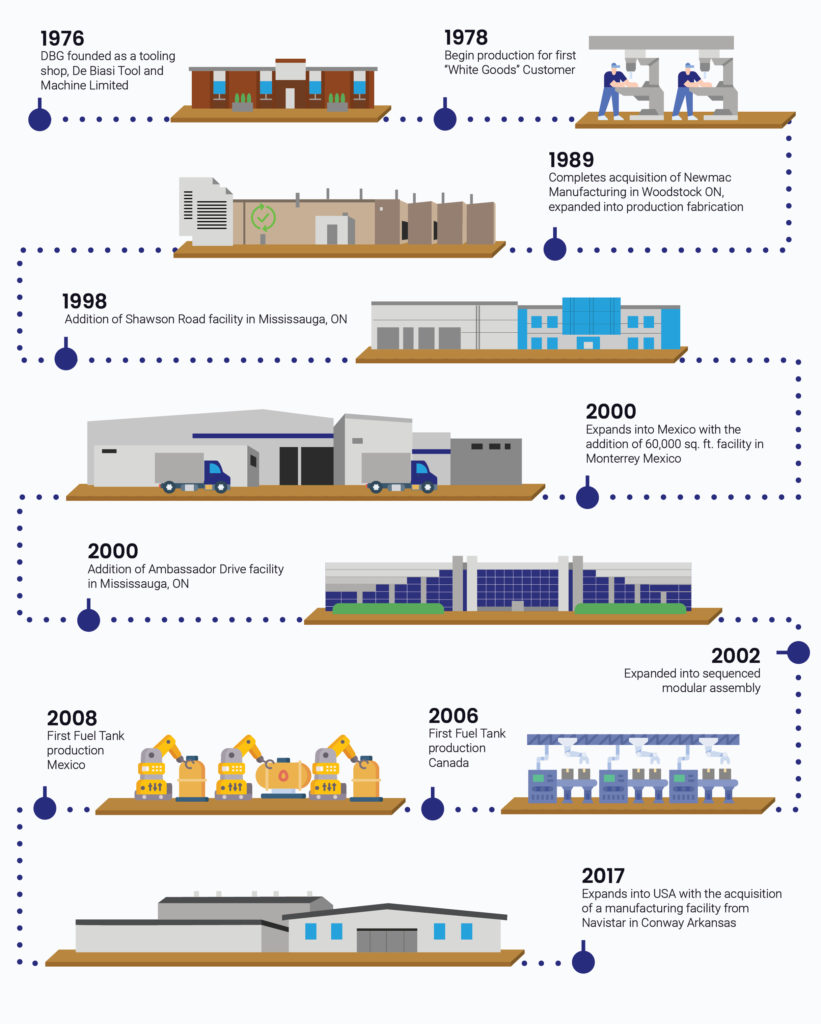

DBG has 5 facilities strategically located in 3 regions across North America to supply our Customers and meet their demand for quality, cost and delivery.

Each DBG Region is operated as a focused business unit, offering Tool and Die resources, Program Management, and a wide range of manufacturing services. This provides Customers with a significant level of local technical expertise and experience while offering the convenience of one supplier to meet their custom metal requirements across North America.

Being in the center of Nuevo Leon and 15 minutes from the Monterrey Airport provides Customers in Mexico and the Southern USA a local source for supply.

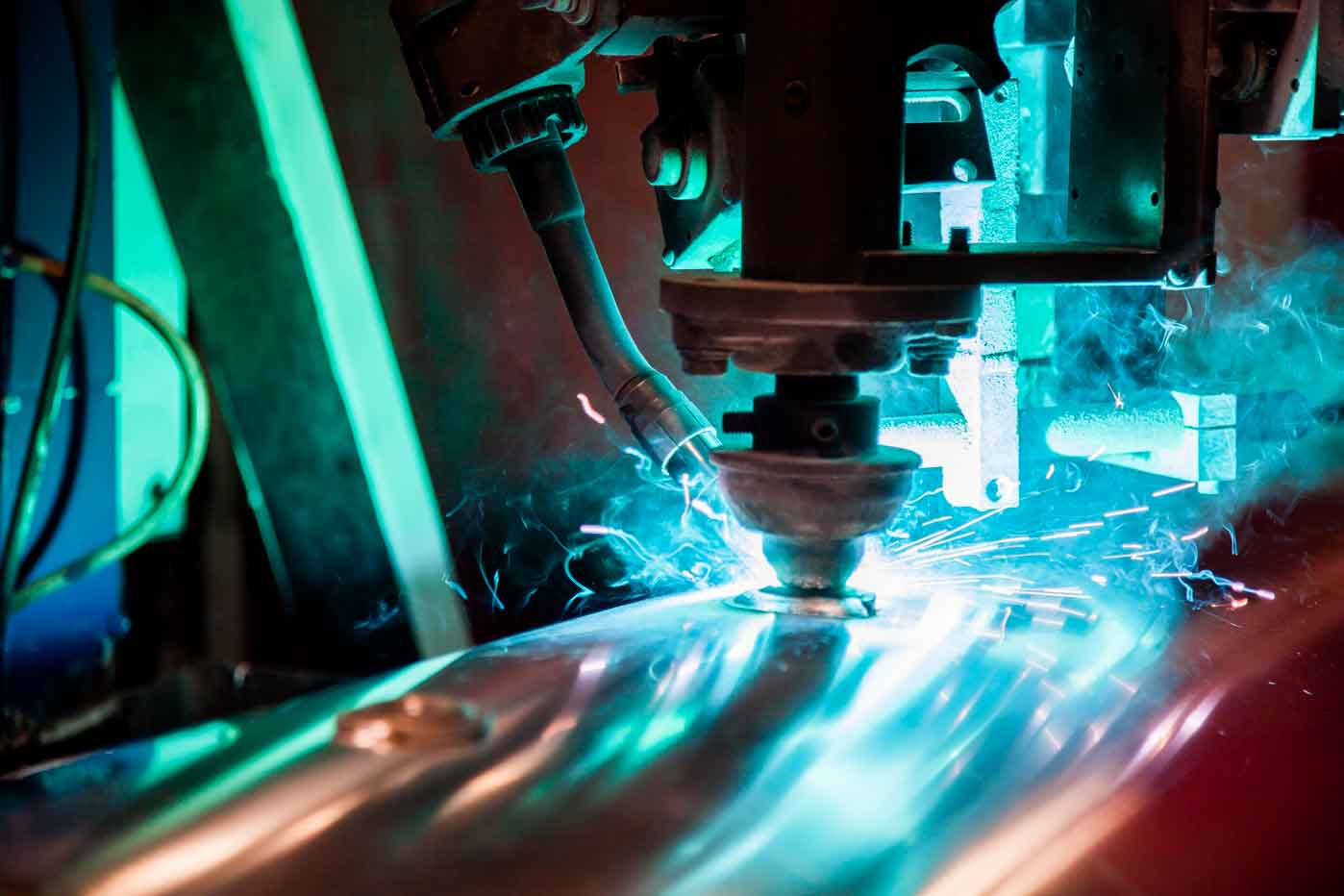

The combined 225,000 square feet of production space is set up to offer the flexibility of low-volume standard tooled products using CNC press brakes, fiber-optic lasers, CNC turrets and other standard equipment, while also being capable of supplying higher volume stamped or fabricated components using presses up to 1000 tons with various transfer and feedline equipment.

Both facilities are supported with auxiliary equipment including manual & robotic weld cells and automated assembly lines for products that require assembly and modular assembly.

The facilities support Customers in the Commercial Vehicle (Bus, Heavy & Medium Duty Truck), Automotive, Military, Agricultural, Construction & Consumer Goods industries.

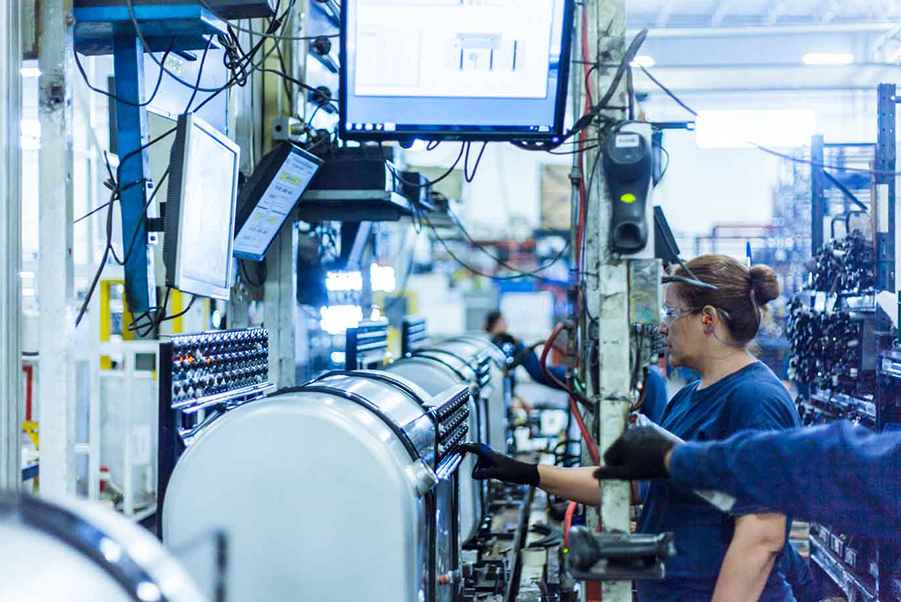

DBG Mexico is DBG’s leading facility with respect to manufacturing 4.0 readiness. The interconnectivity of information from the physical operations to provide real time data for analysis and decision making has provided significant results with respect to quality and delivery. They lead the initiative globally for DBG and they continue to add integration into every aspect of their management and production processes.

Located 25 minutes outside of Little Rock, Arkansas these facilities are set up to offer a wide range of production options to meet Customer’s custom metal needs in the South and Midwest USA.

Over 525,000 square feet of combined manufacturing space provides Customers with the flexibility of low-volume standard tooled products using CNC press brakes, fiber-optic lasers, CNC turrets and other standard equipment. The facilities also have stamping capabilities up to 750 tons.

Both facilities are supported with auxiliary equipment including manual and robotic weld cells, other assembly equipment and a wet on wet prime and topcoat paint line.

These facilities are currently manufacturing products for the Heavy/Medium Duty Trucks, School Bus, Military and Consumer Goods Industries.